Cannabis distribution companies face increasing pressure to reduce carbon emissions and enhance sustainability across their supply chains. One area ripe for transformation is transportation—the backbone of cannabis logistics. By adopting energy-efficient solutions, distributors can cut costs, reduce environmental impact, and position themselves as responsible, forward-thinking operators in a heavily regulated industry.

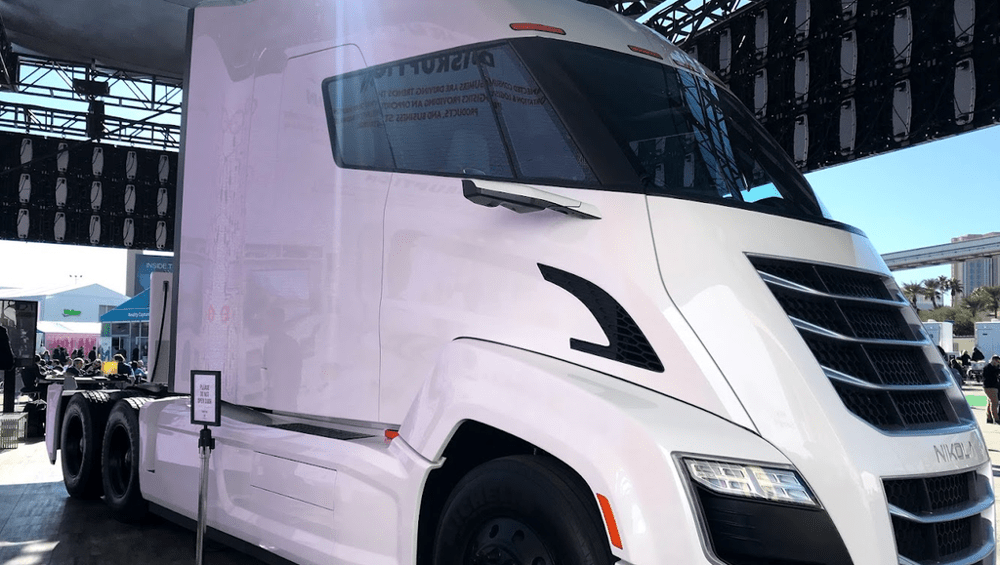

Electric freight vehicles are emerging as one of the most impactful technologies available to cannabis transporters. Heavy-duty electric trucks equipped with charging-optimized routing algorithms can reduce carbon emissions by as much as 28% compared to diesel rigs. Beyond tractor-trailers, adoption of electric cargo vans—such as the Ford E-Transit or Mercedes eSprinter—is gaining traction in urban distribution, providing zero-tailpipe emissions and lower lifetime operating costs. In fact, major carriers like DHL and Amazon have announced plans for deep electrification of their fleets, signaling growing infrastructure support and market readiness.

For campus-style operations—such as warehouses, distribution centers, or intermodal sites—electric terminal tractors offer another route to efficiency. U.S. provider Orange EV pioneered battery-electric yard trucks that eliminate diesel idling while moving trailers on site. Deployed across logistics hubs and ports, they improve air quality and lower maintenance costs.

In addition to switching vehicle powertrains, distributors should pursue idle-reduction solutions—the often-overlooked, low-hanging fruit. Technologies like auxiliary power units and truck-stop electrification can cut idling emissions and fuel consumption dramatically. The Department of Energy estimates that eliminating long-duration idling could reduce CO₂ emissions from trucks by millions of tons annually.

Route optimization and freight consolidation also play critical roles. Advanced transport management systems enable cannabis haulers to implement intelligent routing and to share loads across carriers—reducing empty miles and bolstering delivery efficiency. One analysis of cooperative truck platooning in Europe demonstrated fuel savings of over 5%, with emissions dropped accordingly.

Urban distribution presents unique opportunities too. E-bikes and electric trikes, leveraged for last-mile deliveries especially in densely populated areas, are extremely energy efficient. For example, cargo e-bikes use 1 kWh per 100 km and cut delivery emissions substantially. DHL’s use of 6,100 e-bikes in Germany has eliminated approximately 1 million metric tons of CO₂ per year. Cannabis dispensaries—often located in urban zones—can partner with local couriers offering zero-emission bike delivery to green their distribution and appeal to eco-conscious clients.

Infrastructure also matters. Distribution sites equipped with solar photovoltaic arrays, motion-sensor lighting, and vehicle charging stations maximize operational sustainability and reduce grid dependence. As seen at the 7 Stars Holistic Healing Center in Richmond, VA, offering EV charging attracts green-minded suppliers and supports collaborative sustainability goals.

Lastly, federal and state energy-efficiency grant programs—like the USDA’s REAP grants and Energy Star building standards—are available to help offset the cost of electrification, charging infrastructure, and facility upgrades.

In summary, cannabis distributors can significantly advance sustainability through a multi-pronged approach: electrifying vehicle fleets, minimizing idling, optimizing routing, adopting last-mile e-mobility solutions, and leveraging facility upgrades and available grants. Doing so not only shrinks carbon footprints but strengthens compliance posture and brand reputation in a rapidly maturing industry.